|

|

|

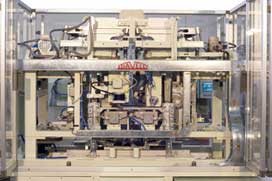

Horizontal Form Fill Seal machine for long pasta with integrated weighing system-

SO NEW-S ELECTRONIC is an innovative machine

suitable for packing products such as long cut pasta,

bread sticks, chocolate bars, etc. in pillow type bags

and also in flow-packed trays if supplied with some

special devices. SO NEW-S ELECTRONIC is the

result of many years of field experience and machine

development.

These improvements have further increased the

well known reliability of STIAVELLI long cut pasta

packaging systems.

The packaging system shown on this page is the

long cut pasta version of the SO NEW-S ELECTRONIC

machine equipped with SPL/E NEW-S double weighers.

- High speed reliable packaging system, with

excellent weighing accuracy.

- Electronic management of all machine

parameters thanks to the multitask operator

interface.

- Minimum percentage of rejected packs due

to product contaminated seals.

- High performance machine able to handle

rough and difficult flowing products.

- High quality of components sharply reduces

parts wear and consequently maintenance time.

- Phased electronic control with automatic

resetting after any machine stop.

- Operator interface (weigher + packaging

machine) with touch screen color display

for memorization, control and self-diagnostic

of all operation parameters.

Possibility of remote control through modem

or via Internet.

- Sturdy steel structure designed to absorb

vibration at the highest production speed.

- All product contact parts are in stainless

steel or teflon.

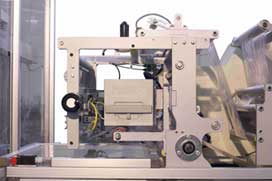

- Main machine movements (feeding channel,

leveling group, driving roll film longitudinal

sealer, sealing jaws and transversal cut) are

driven by brushless independent servo motors.

- Self-adjusting breaking devices for reel holding

spindles and film servo unwinding roll with

adjustable speed to give film constant tension.

- Automatic film width centering device and

machine stop device for film breakage

controlled and regulated by fiber optic sensors.

- Empty bags ejecting device used during

automatic reel changing phase or in case

of pack ejection due to product contaminated

seals.

- Independent electric panel with machine cycle

control by PLC and axis electronic cards.

- Single product feeding point with independent

initial and final weight vibrating chutes, also

equipped with side leveling device.

- Final weighing groups driven

by stepper motors.

- Initial weighing groups driven by pneumatic

cylinders.

- Final weight automatic continuous adjustment

groups driven by stepper motors with memorized

positioning at changeover.

- Double feeding cell of the strain-gauge type

for each weighing group.

- Product transfer trolley and unloading flap for

connection of weighers to packaging machine

driven by step motors.

- Independent electric panel.

- Special profile sealing unit.

- Double reel support.

- Perforation date unit.

- FSA doser for curl edge shapes up to

25 mm wide.

- Ejecting device for the packs with product

in the seals.

Complete turn-keys food processing and packaging solutions are available on request.

Please contact us on info@jzw.com.au to discuss your application. |

|